Worried about long manufacturing lead time?

Experience a transformative 10 days with Vren as your business partner. Curious? Explore our manufacturing flowline for an insight into the efficiency and excellence defining our partnership.

Professionally qualified team with vast experience in world-class manufacturing industries.

Blossom engineers emphasizes rigorous quality assurance in heavy metal fabrication. Through systematic monitoring, testing, and adherence to industry standards, blossom engineers ensures high-quality products, reflecting its commitment to client satisfaction.

Precision through a systematic quality assurance.

Dedicated to delivering top-notch solutions.

Rigorous testing and adherence to industry standards.

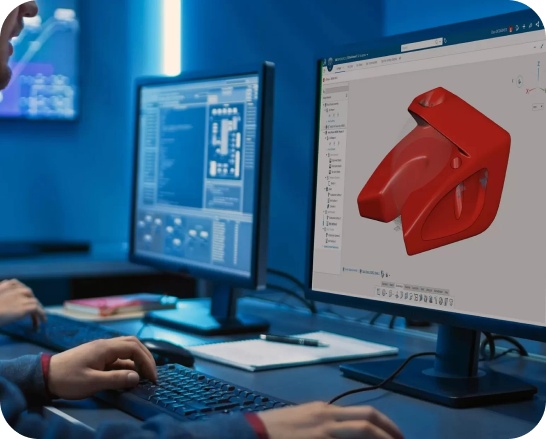

Design

Our tailored approach ensures bespoke product design, incorporating your specifications and logo. Our adept design engineers possess extensive expertise in attachments and working parameters. Upon completion, design drafts undergo your scrutiny. Following approval, manufacturing drawings are promptly released for fabrication, seamlessly aligning our solutions with your unique needs and preferences.

Advanced CNC & Premium Steel

The unit is powered by two high precise Plasma Cutting Machines, One Four-Roll CNC rolling machine, One Hydraulic CNC Press Brake of 400 Tons and having a steel Inventory of 100 Tons every time. We use premium steel and cast parts like SSAB Hardox450/500TUF / STRENX 700MCE, DILLINGER DILLIDUR400/500 & DILLIMAX 690, JSW-G250/350/450

25-Station Welding Bay

A well organized Fit up and Welding Bay of 25 Stations giving a daily output of 15 Tons. We carry out MIG-MAG welding using E71T-1 Flux cored wire for the best sustainability of the Attachments.

Spacious Storage with In-Line Quality

Spacious bay to store all the kits and fabricated products with IN-LINE quality system. We use ESCO, MTG, HENSLEY, CAT GET, 500 BHN Bolt on Cutting Edges and 500 BHN cutting edge/blade, Assembled with Plow bolts of 12.9 Grade; Adequate Torque Tightened.

Predefined Painting & Efficient Packing Process

We have a good predefined painting sequence, which starts from Grit Blasting, Priming and Painting. After Paint, the products are moved into the Packing Section, where PDI is carried out and the parts are loaded into the Container. We also make sure your logistics price is fully utilized by stuffing adequate parts into the Container.

Logistics

Our adept logistics team handles every aspect of your shipment, from container placement to de-stuffing. They meticulously track the container, providing timely updates on cargo ETA. With their expertise, your logistics process is seamlessly managed, ensuring efficiency and keeping you well-informed throughout the transportation journey.

Impressed seeing our work flow line? You can witness it live at our facility!

Visit us

#171/1, Poonapalli, Thally Main Road, Hosur, Tamil Nadu, India 635109

Terms and conditions

Privacy Policy

© Copyright 2024, All Rights Reserved by Blossom Engineers